Don’t buy a cheap rotary valve

09/03/2022

Frequent clogs. Wasted material. Time lost on cleaning and repairs. And literal holes pitted throughout the structure of your rotary valve.

That’s what you get when you buy the cheapest possible valve. Not to scare you or anything, but a cheap valve can cost you more money and hassle in the long run. The right valve, on the other hand, actually saves money and makes your job easier.

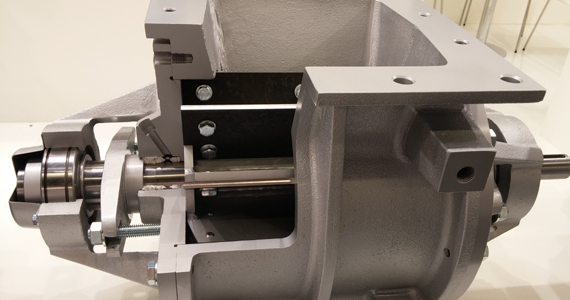

The quality can be a little… unreliable. Oftentimes that makes the machine itself looks rough and porous, like it wasn’t cast properly. With a valve like this, you might notice pitting, air holes or increased clearances where air can leak through.

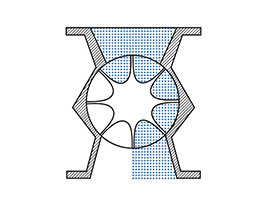

This is especially bad if you’re conveying an abrasive product, because improper clearances create a kind of cyclone that sandblasts the holes and makes them worse as the rotor blades turn. That’s a big no-no in sanitary applications, because bacteria can proliferate in holes and pitted areas.

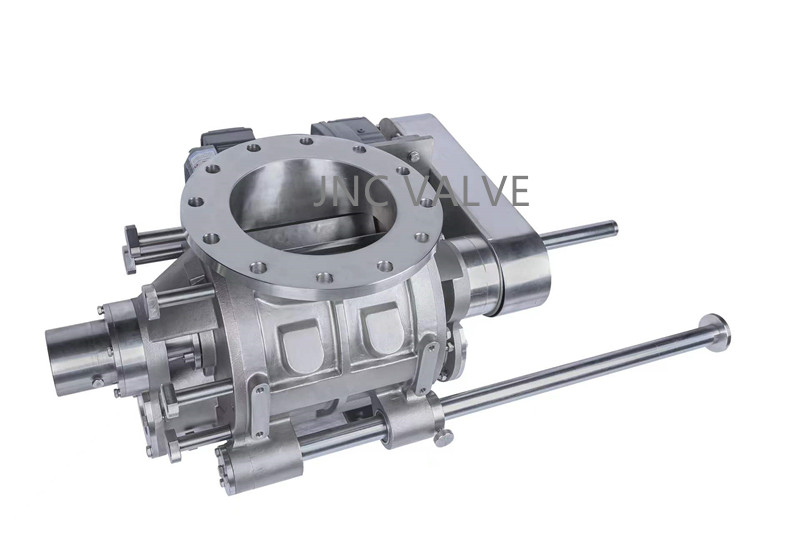

With plenty of configuration options, as well as valves that can handle high temperatures and pressure differentials, we can ensure your valve runs smoothly for years to come.

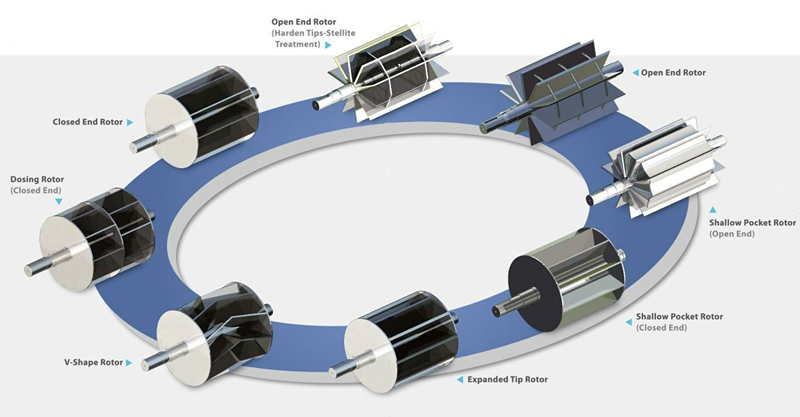

To get the most efficient rotor pocket capacity and consistent material throughput, accurate rotary valve sizing is essential. Depending on your material, the right size can also help extend the valve’s maintenance cycles and lifespan — for example, by preventing material from building up on the inlet flange, or by reducing wear in more abrasive applications.